* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

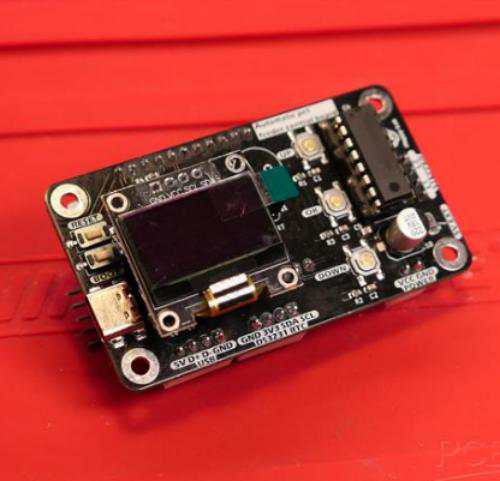

Product Description: Premium PCBA for Smart Pet Feeders

Our Pet Feeder PCBA is a high-quality, customized printed circuit board assembly specifically designed for intelligent automatic pet feeding systems. Whether you're manufacturing smart feeders for cats, dogs, or other small pets, our PCBA solution provides a robust, efficient, and highly integrated control system that powers reliable and accurate pet feeding experiences.

This PCBA is engineered to support advanced functionalities such as:

Scheduled feeding

Mobile app connectivity via Wi-Fi/Bluetooth

Real-time video monitoring (optional camera integration)

Voice interaction or sound playback

Food level detection (sensor interface)

Emergency backup battery switching

Touch screen or button control

The Pet Feeder PCBA is manufactured with precision and attention to detail, ensuring long-term durability and consistent performance in various operating environments.

Materials Selection: Components That Matter

To ensure our pet feeder PCBA meets the highest industry standards and functions efficiently in smart home ecosystems, we emphasize premium material selection:

1. PCB Base Material:

FR4 Epoxy Glass Laminate: Flame-retardant, thermally stable, and cost-effective, ideal for standard consumer electronics.

TG150-TG180 High Tg PCBs: For enhanced thermal performance in pet feeders with heating, motorized dispensing, or embedded video cameras.

2. Copper Foil:

1oz to 2oz Copper Thickness: Standard 1oz for signal layers and 2oz for power circuits and motor drive sections, ensuring optimal current-carrying capacity.

3. Surface Finish:

ENIG (Electroless Nickel Immersion Gold): Ensures excellent solderability and oxidation resistance, particularly beneficial for exposed pads and fine-pitch components.

OSP (Organic Solderability Preservative): Cost-effective and environmentally friendly option for basic models.

4. Key Components:

MCU/SoC: STM32, ESP32, or customized chips for IoT control, sensor input, and app integration.

Real-Time Clock (RTC): For feeding schedule accuracy.

Motor Drivers: For stepper motor or DC motor control used in food dispensing.

Sensor Interfaces: Infrared, ultrasonic, or load cell for food presence/weight monitoring.

Connectivity Modules: Wi-Fi/Bluetooth modules (e.g., ESP-WROOM-32) for smart interaction.

Battery Management ICs: For uninterrupted feeding operation during power loss.

High-Performance Pet Feeder PCBA

PCBA Manufacturing Process for Pet Feeder Applications

1. PCB Fabrication:

We start by fabricating multi-layer PCBs using high-grade raw materials. The fabrication process involves:

Layer stack-up design for signal integrity

Precise drilling and plating through holes

Copper etching and pattern transfe

Solder mask application

Surface finishing (ENIG/OSP)

Silkscreen printing

2. Component Sourcing:

All electronic components are sourced from authorized distributors like Digi-Key, Mouser, and Arrow to ensure traceability and authenticity.

3. SMT Assembly (Surface Mount Technology):

High-speed SMT lines place 0201, QFN, BGA, and other components with high accuracy

AOI (Automated Optical Inspection) after reflow soldering for defect detection

X-Ray inspection for BGA and hidden solder joints

4. THT Assembly (Through-Hole Technology):

Manual or automated insertion of larger components such as pin headers, motors, or terminal blocks

Wave soldering or selective soldering depending on design complexity

5. Conformal Coating (Optional):

For moisture or dust protection in long-term usage, especially for outdoor pet feeders.

6. Functional Testing:

Custom test jigs for verifying all critical functions (e.g., motor drive, sensor input, Wi-Fi communication)

Firmware pre-burning and debugging

Aging tests for thermal and load performance

Manufacturing Considerations & Best Practices

To ensure reliability and functionality of our pet feeder PCBA, the following design and manufacturing guidelines are strictly followed:

1. Power Supply Design:

Multi-voltage regulation to support motors, logic circuits, and sensors

Reverse polarity protection and transient voltage suppression

2. EMI/EMC Control:

Proper grounding, filtering, and shielding to minimize interference from motors or Wi-Fi modules

3. Thermal Management:

Thermal vias, copper pour, and heat sinks for power ICs and motor drivers

Use of high Tg substrates for thermal resilience

4. PCB Layout Optimization:

Separation of analog and digital ground planes

Short and shielded traces for high-speed signal paths

Optimized routing for differential pairs (USB/Wi-Fi antennas)

5. Mechanical Design Compatibility:

Board cutouts and mounting holes aligned with the pet feeder casing

Antenna placement optimized for wireless signal strength in plastic enclosures

High-Performance Pet Feeder PCBA

Quality Control & Assurance

We follow a strict quality management system to ensure every Pet Feeder PCBA is delivered with zero defects:

1. IPC Standards Compliance:

Assembling according to IPC-A-610 Class II/III, depending on client requirements

2. 100% E-Test for Bare Boards:

Continuity and short circuit tests before SMT process

3. Automated Optical Inspection (AOI):

Every board is inspected post-reflow to detect placement errors, solder bridges, missing components, and polarity issues

4. X-ray Inspection:

Focused on BGAs, QFNs, and double-layer soldering to ensure hidden joints are defect-free

5. In-Circuit Test (ICT):

For mass production, we implement ICT to test individual components and signal paths

6. Functional Test (FCT):

Full-system simulation testing for feeding cycle, connectivity, sensor response, and user interface

7. Environmental Testing (Optional):

Thermal cycling, humidity testing, vibration simulation if required for harsh environment models

Applications of Our Pet Feeder PCBA

Our PCBAs can be integrated into a wide range of smart pet care products:

Smart pet feeders with mobile app control

Multi-pet feeders with portion control

Pet feeders with cameras and voice commands

Outdoor automatic feeders for stray animals

Timed dispensers for medication or treats

Why Choose Us for Pet Feeder PCBA Manufacturing?

OEM & ODM Support: Custom design, firmware development, and PCBA integration

Component Procurement: 100% genuine, RoHS/REACH compliant parts

Fast Turnaround: Prototype in 7-10 working days; mass production in 15-20 days

Full Testing Coverage: From AOI to real-life functional testing

One-Stop Solution: From PCB design to box-build assembly

Get in Touch for Your Custom Pet Feeder PCBA Project

Whether you're a startup developing an innovative pet care product or an established brand looking to scale, we can provide tailor-made pet feeder PCBA solutions that meet your budget, timeline, and technical requirements. Contact us today to request a quote, review your design files, or get engineering support!

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108