* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

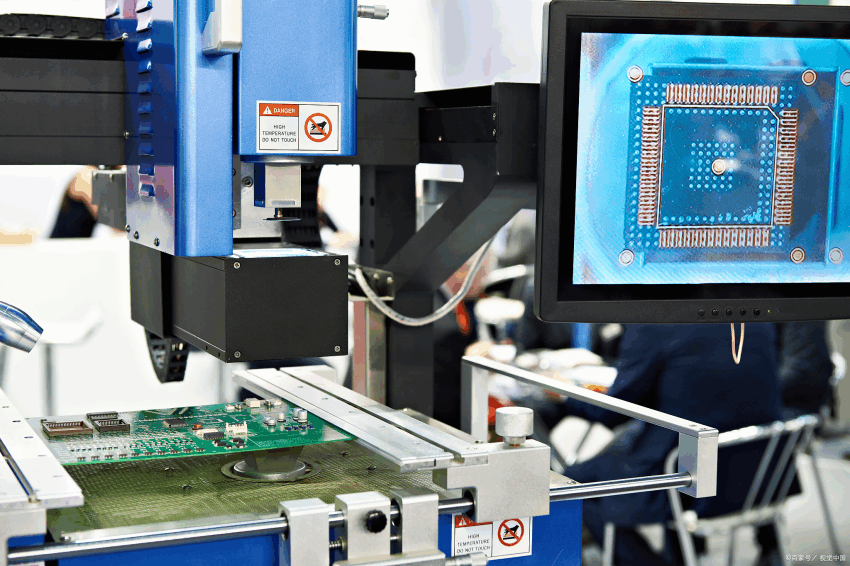

SMT Soldering Process

SMT (Surface Mount Technology) surface mount technology is one of the most widely used technologies in PCBBA manufacturing. It uses automated equipment to precisely place surface-mounted components onto the pads of the PCB board, and then, through reflow soldering, melts the solder paste to achieve electrical connection and mechanical fixation between the components and the PCB. During this process, the accuracy and stability of the equipment are of vital importance. For instance, high-speed surface mounters can complete the component mounting at extremely high speed and with high precision, significantly enhancing production efficiency. Meanwhile, for some micro-sized components, such as resistors and capacitors in 01005 packaging, higher precision equipment and more meticulous process control are required to ensure the accuracy of the mounting and the quality of the soldering.

PCBA

DIP Plug-in Process

The DIP (Dual In-line Package) assembly process is suitable for some components with longer pins, higher power, or higher requirements for mechanical strength, such as electrolytic capacitors and sockets. Operators or automated assembly equipment insert the pins of the components into the corresponding through-holes on the PCB board, and then use wave soldering to weld the pins to the pads. During the wave soldering process, the PCB board passes through the molten solder wave, and the solder, under the action of surface tension and flux, fills the gap between the pins and the pads, forming a reliable solder joint. However, the DIP assembly process is relatively complex, has lower production efficiency, and higher costs. Nevertheless, it is still indispensable in certain scenarios.

Key Points for Welding Quality Control

Welding is a crucial step in the PCB assembly process, and the quality of the welding directly affects the performance and reliability of the product. Common welding defects include incomplete welding, bridging, and cracking of solder joints. Incomplete welding occurs when a good intermetallic compound is not formed between the solder and the component pins or the PCB pads, resulting in unreliable electrical connections and frequent contact problems during product use. Bridging refers to the connection of solder between adjacent solder joints, causing short circuit faults. To avoid these problems, it is necessary to strictly control the welding temperature curve, the quality and quantity of the solder, the selection of flux, and the parameter settings of the welding equipment. For example, the temperature curve for reflow soldering needs to be optimized according to different components and PCB materials to ensure that the solder paste melts and solidifies at the appropriate temperature, while avoiding excessive temperatures that may damage the components.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108