How to cope with the miniaturization trend of industrial robot vision systems in industrial control SMT processing?

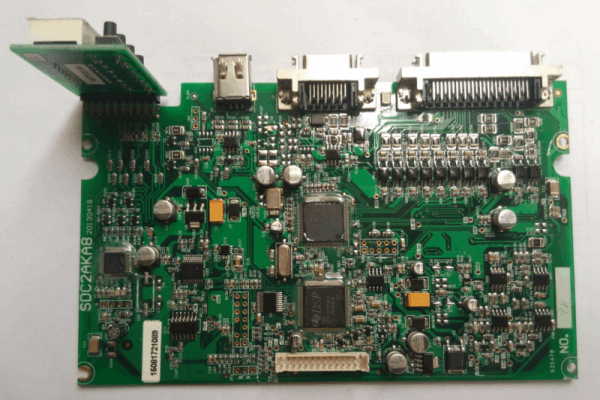

With the accelerating trend of miniaturization in industrial robot vision systems, industrial control SMT processing faces higher challenges in terms of accuracy, efficiency, and reliability. The core functions of industrial robot vision systems rely on high-density, high-performance electronic components, and the industrial control PCBA circuit board, as its hardware foundation, must adapt to this trend through technological innovation and process optimization. The following are key strategies for industrial control SMT processing to cope with the miniaturization trend.

The Challenges of Miniaturization Trends for Industrial Control PCBA Processing

The miniaturization of industrial robot vision systems requires PCBA to have higher integration and smaller size, which poses the following challenges to industrial control SMT processing:

- Component size reduction: For example, the use of ultra-small components such as 0201 and 01005 places higher demands on mounting accuracy and soldering reliability.

- High-density layout: Miniaturized circuit boards require denser layout and more complex interlayer designs, increasing the difficulty of design and manufacturing.

- Thermal management pressure: High integration leads to increased local heat generation, which requires material selection and optimization of heat dissipation design to solve the problem of heat accumulation.

- Cost control: Miniaturization processes (such as laser etching, micro-welding) may increase production costs, requiring a balance between performance and economy.

Coping Strategies for Industrial Control SMT Processing

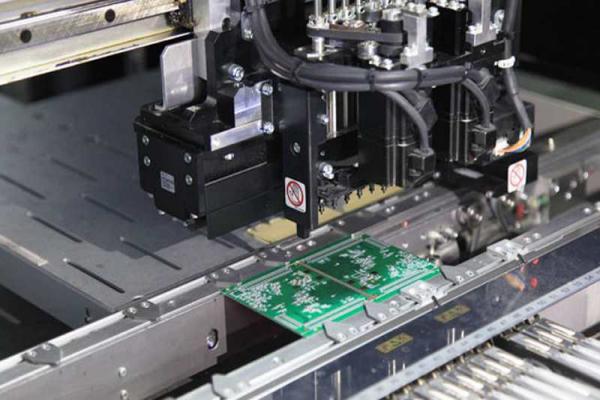

1.High-Precision Placement Technology Upgrade

* Visual Alignment System Optimization: Utilize multi-spectral imaging technology to eliminate solder pad oxidation interference, achieving a placement accuracy of ±25μm, ensuring reliable placement of micro components such as 0201.

* Dynamic Compensation Algorithm: Improve positional consistency during high-speed placement by automatically correcting mechanical errors of the equipment, meeting the rapid assembly needs of high-density components.

* Clamping Technology Improvement: Reduce PCB deformation through precision clamping devices, enhancing the stability of micro component placement.

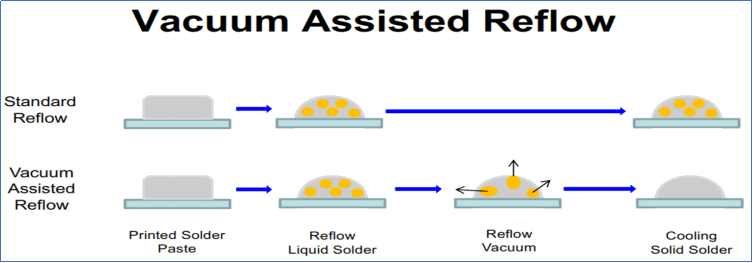

2. Reflow soldering process improvement

* Temperature Curve Optimization: For micro components (such as 0.3mm pitch BGA), nitrogen protection + infrared/hot air composite heating technology is used to control the solder joint void ratio below 0.01%.

* Stencil Printing Process: Improve stencil aperture design and solder paste formula to ensure solder paste printing uniformity of micro pads and increase soldering yield to over 99.95%.

* Material Selection: Use high thermal conductivity substrates (such as ceramic substrates) and low residue flux to reduce thermal stress and soldering defects.

3. End-to-end reliability control

* Cleanliness Management: Make production in a clean room (≥0.5μm particle control), combine with plasma cleaning technology to remove flux residues and avoid electrochemical migration (ECM) risks.

* Conformal Coating Process: Polyurethane (PU) coating with a thickness of 50-80μm and edge coverage >90% is applied to enhance the reliability of the PCBA in humid and vibrating environments.

* Structural Reinforcement Design: Key components such as connectors and sensors are reinforced with epoxy adhesive. The DO-160 vibration test need be passed to ensure the stability of the industrial robot vision system under complex working conditions.

4. Intelligent manufacturing and testing

* Machine vision-assisted inspection: AOI (Automated Optical Inspection) systems, combined with AI algorithms (such as deep learning), can identify defects such as voids and offsets in micro solder joints, improving inspection efficiency by more than 50%.

* X-ray inspection: High-resolution X-ray equipment is used to detect internal defects in hidden solder joints such as BGAs and QFNs, ensuring that the soldering quality meets the IPC-A-610 Class 3 standard.

Conclusion

The miniaturization trend of industrial robot vision systems brings both opportunities and challenges to industrial control SMT processing.

Kingsheng PCBA has been focusing on the production of industrial control PCBA for many years, providing high-performance and high-reliability hardware support for industrial robots through

high-precision mounting technology,

advanced welding processes, and

full-process reliability control and

testing methods. With the continuous advancement of technology, industrial control SMT processing will play a more central role in the field of intelligent manufacturing.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108