Why drone circuit boards need to be coated with conformal coating?

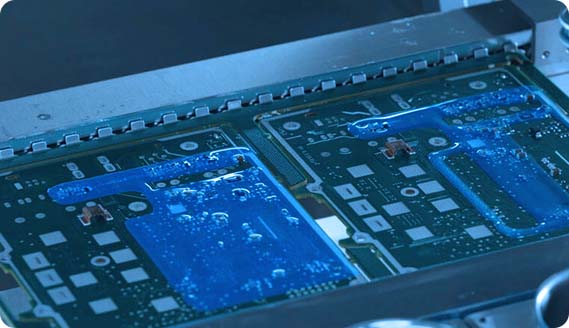

As the core carrier for flight control, power management, and communication transmission, the reliability of drone circuit boards directly affects the overall performance and flight safety. However, drones often face harsh environments such as humidity, salt spray, vibration, and extreme temperatures, making the precision components on the circuit board (such as MCUs, sensors, power MOSFETs, etc.) highly susceptible to failure due to environmental erosion. Conformal Coating significantly enhances the environmental resistance of circuit boards by forming a highly protective thin film. This article, based on the design characteristics of drone circuit boards and supported by measured data, analyzes the key roles of conformal coatings.

1.Protection Challenges of Drone Circuit Boards and the Necessity of Conformal Coating

1.1 Protection Challenges Arising from High-Density Integration

Modern drones require lightweight design and high performance. Drone circuit boards commonly adopt HDI designs with 4-8 layers, and the component spacing is typically less than 0.5mm (such as 0402 resistors and capacitors, and QFN ICs). High-density layout leads to:

- Reduced creepage distance increases the likelihood of conductive anodic filament (CAF) formation in humid environments, leading to short circuits.

- Exposed solder joints are susceptible to salt spray corrosion, which can cause an increase in solder joint impedance (actual data: unprotected PCBs showed a 300% increase in solder joint resistance after 48 hours of salt spray testing).

Conformal coating effectively inhibits electrolytic corrosion by filling the gaps between components to form an insulating barrier. Experiments show that a PCB coated with 25μm polyurethane conformal coating has an insulation resistance>10^12Ω in an environment of 85%RH humidity + 85℃, while the insulation resistance of an uncoated PCB is only 10^8Ω, a difference of 4 orders of magnitude.

1.2 Miniaturization and High-Frequency Signal Integrity Requirements

The working frequency of drone flight control, image transmission and etc. can reach 2.4GHz (WiFi) - 5.8GHz (FPV). The dielectric constant (Dk) and dissipation factor (Df) of the conformal coating directly affect the signal quality. For example:

- Inferior conformal coating (Dk>3.5) will cause signal delay and affect the response speed of PID control.

- High-loss materials (Df>0.02) will increase insertion loss and reduce image transmission distance.

Experimental data: After a certain type of drone adopted modified acrylic conformal coating (Dk=2.8, Df=0.008), the signal attenuation in the 5.8GHz frequency band decreased by 15%, but the image transmission stability improved.

1.3 Vibration and mechanical stress impact

When drones take off, land, or perform maneuvers, the circuit board bears 5-20G vibration shock, which can easily lead to:

- BGA solder joint cracking (failure rate >30% for unprotected PCBs in random vibration tests).

- MLCC (multi-layer ceramic capacitor) fracture, causing power supply failure.

The elastic modulus of conformal coating (typically 0.1-1GPa) can absorb mechanical stress. For example, after a certain industrial drone adopted silicone conformal coating (elastic modulus of 0.3GPa), the pass rate of vibration test (10-2000Hz, 3 axes, 15min each) increased from 70% to 98%.

2.Key Protective Performance and Data Verification of Conformal Coating

2.1 Moisture Resistance (IPC-CC-830B Standard)

- Uncoated PCBs showed 40% solder joint corrosion after damp heat testing (85°C/85%RH, 1000h).

- PCBs coated with polyurethane conformal coating (25μm) showed no corrosion under the same conditions, and the surface insulation resistance was >10^11Ω.

2.2 Salt spray resistance (ASTM B117)

- Unprotected PCBs showed copper foil corrosion area >50% after 96h after 5% NaCl salt spray test.

- PCBs coated with epoxy resin conformal coating remain intact after 500h of salt spray testing.

2.3 High and low temperature cycling (-40℃~125℃)

When drones operate in high-altitude/desert environments, the temperature of the circuit board fluctuates dramatically.

Experimental data: After 1000 temperature cycles, the coating of the PCB coated with modified silicone conformal coating showed no cracking, and the components functioned normally.

Conclusion

Conformal Coating is the "Invisible Guardian" of Drone Reliability

Experimental data shows that conformal coating can significantly improve the following aspects of drone circuit boards:

- Moisture Resistance (Damp Heat Test Pass Rate >95%)

- Salt Spray Resistance (500h salt spray without corrosion)

- Vibration Resistance (BGA solder joint failure rate <2%)

- High-Frequency Signal Integrity (5.8GHz insertion loss <0.5dB)

In the future, with the application of Nano Coatings and Self-Healing Materials, the protective capabilities of conformal coatings will be further enhanced, becoming a key guarantee for the long life and high reliability of drones.

Kingsheng PCBA is dedicated to high-end HDI, multi-layer PCB, high-frequency and high-speed PCB, FPC, rigid-flex PCB, SMT processing, and PCBA assembly with components sourcing. We provide

one-stop PCB and PCBA manufacturing services with

fast turnaround, engineer accountability system, and a 5-year free warranty, making your PCBA manufacturing simple and efficient.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108