Why Kingsheng PCBA suggests using surface mount technology(SMT) to design Elevator Drive PCBAs?

In the modern vertical transportation field, elevator systems are crucial for the smooth operation of residential, commercial, or industrial buildings. The elevator drive PCBA is the core of these systems, serving as the key part for managing and coordinating all aspects of elevator operation.

The elevator drive PCBA is designed to meet the specific requirements of elevator systems, ensuring reliable communication, precise control, and high safety standards.

Using Surface Mount Technology (SMT) in elevator drive PCBA production offers several significant advantages compared to traditional Through-Hole Technology. These advantages contribute to higher quality, reliability, and cost-effectiveness of the final product:

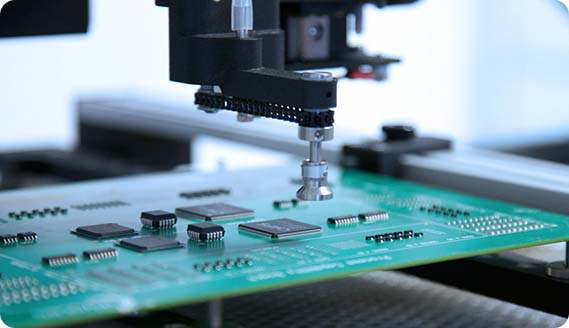

High-Precision Assembly

SMT technology enables the precise placement of components on PCBs. Automatic pick-and-place machines can accurately position even the smallest components, such as surface-mount resistors, capacitors, and integrated circuits. This precision ensures reliable electrical connections and reduces the risk of errors during assembly. For example, when placing a microcontroller on an elevator drive PCBA, SMT technology ensures proper pin alignment, enabling normal communication and control functions.

Improve Production Efficiency

The SMT assembly process is highly automated, significantly improving production efficiency. Machines can quickly place multiple components onto the PCB in a single operation, thereby reducing overall assembly time. Furthermore, compared to traditional manual soldering or wave soldering, SMT uses reflow soldering, which is a faster and more efficient soldering method. This shortens the production cycle, increases output, and enables manufacturers to meet the growing demand for elevator drive PCBAs.

Increase Component Density

SMT allows for the integration of a large number of components into a smaller PCB area. Surface mount components are typically smaller in size than through-hole components, resulting in higher component density. This is crucial for elevator drive PCBAs, as they need to integrate various functions and features within a limited space. Packing more components onto the PCB can also reduce the overall size and weight of the elevator control system, making it more compact and energy-efficient.

Improve product quality

SMT process reduces the risk of human error during assembly, thereby improving product quality. Automated inspection systems can be used to check component placement and soldering quality, ensuring that each PCBA meets the required standards. In addition, SMT uses high-quality solder paste and a controllable soldering process, making the connection between components more secure and reliable, thereby reducing the possibility of long-term component failure.

Cost Savings

Increasing SMT production efficiency, reducing labor costs due to automation, and lowering open circuit rates all contribute to reducing overall costs.

In addition, smaller SMT component sizes can save on material and packaging costs. These cost advantages make elevator drive PCBAs more competitive in the market.

Kingsheng PCBA has 15-years experience from PCB manufacturing, PCB assembly, component sourcing, programming, and testing. We provide BOM cost optimization by qualified alternatives with strong supply chain, saving your cost and stabilizing your market share in the current economic situation.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108