* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

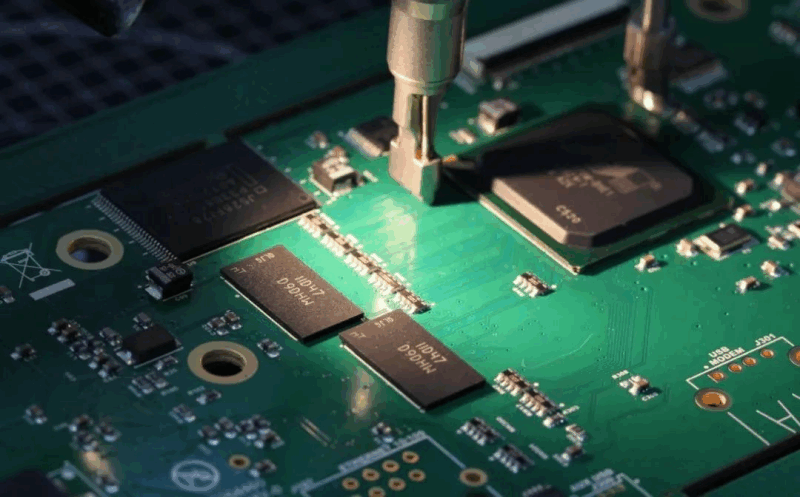

In the modern electronics manufacturing field, the quality of PCBA (Printed Circuit Board Assembly) directly determines the performance and reliability of the final product. As a one-stop PCBA manufacturer, KINGSHENG always regards zero defects as the lifeline of the enterprise. Today, we will take you to deeply understand how KINGSHENG uses advanced X-ray inspection technology to protect your product quality.

X-ray Inspection: Invisible Defects, Visible Quality

X-ray inspection is an indispensable part of the PCBA manufacturing process, especially when inspecting the soldering quality of hidden solder joints such as BGA (Ball Grid Array) and QFN (Quad Flat No-leads Package), it has an irreplaceable role. Advanced X-ray inspection equipment is capable of:

X-ray Inspection Technology

Why is X-ray inspection critical for PCBAs?

1. Improve product reliability

Soldering defects can cause electronic products to fail when operating in extreme conditions like high temperatures and vibration. X-ray inspection can identify potential issues early, preventing widespread failures.

2. Reduce rework costs

Traditional manual visual inspection struggles to detect hidden defects. X-ray inspection, however, enables real-time monitoring during production, reducing rework and scrap costs.

3. Meeting Industry Standards

Industries with stringent requirements, such as medical, automotive, and industrial control, have strict PCBA quality standards, making X-ray inspection a critical tool for ensuring compliance.

Ensure Your Product Quality

KINGSHENG's X-ray detection capability

KINGSHENG is equipped with multiple high-precision X-ray inspection equipment, including:

Leveraging X-ray inspection data, our engineering team optimized the production process to ensure that every PCBA meets the customer's stringent requirements.

Four Core Advantages: KINGSHENG Helps You Succeed

1. R&D Assistance

Offers PCB design optimization and DFM (Design for Manufacturability) analysis to help customers shorten their R&D cycle.

2. Fast Service

Provides 24/7 technical support, rapid quotations within 24 hours, and efficient delivery through an industry-leading MES system.

3. Zero Defects

Ensures high product quality through 19 quality control processes and advanced testing equipment such as X-ray.

4. One-Stop Service

Offers comprehensive electronic assembly solutions, from design and development to finished product assembly.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108