* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

In smart hardware manufacturing, the transportation packaging of printed circuit board assemblies (PCBAs) directly impacts the final product quality and customer experience. A meticulously designed circuit board can be rendered useless due to transportation mishaps, leading to significant losses. Drawing upon industry experience, this article will outline the key considerations for PCBA transportation packaging, covering everything from packaging materials and protective measures to transportation management.

PCBA Transportation Packaging

1. Preparation Before Packaging: Cleaning and Protection Are Key

Surface Cleaning and Drying

Prior to packaging, circuit boards must be thoroughly cleaned to remove any residual solder debris, dust, and other contaminants. Ensure the surface is completely dry to prevent oxidation or short circuits caused by moisture. Some high-precision boards may also require a conformal coating (moisture-proof, salt spray-proof, and mildew-proof) to improve environmental resistance.

Electrostatic Protection Pretreatment

Static electricity can damage chips, especially sensitive components like MOSFETs. Use anti-static gloves and tools when handling boards before packaging to prevent electrostatic discharge.

PCBA Transportation Packaging

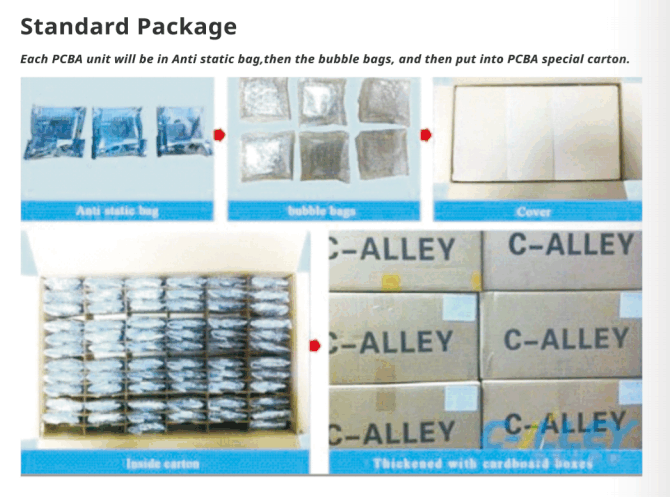

2. Packaging Material Selection: Triple Protection is Key

Anti-static Packaging

Anti-static Bubble Bag/Pink Poly Bag: Dissipates static charges through a special coating, while also providing cushioning.

Shielding Bag (Metallized Anti-static Bag): Ideal for long-distance transport or highly sensitive components, shielding against external electrostatic interference.

Moisture-proof Packaging

Vacuum or Nitrogen Packaging: Isolates contents from oxygen and moisture, making it suitable for long-term storage or marine environments.

Desiccant Assistance: Silica gel desiccant should be placed inside the sealed bag to absorb any remaining moisture, ensuring internal humidity remains below 10% RH.

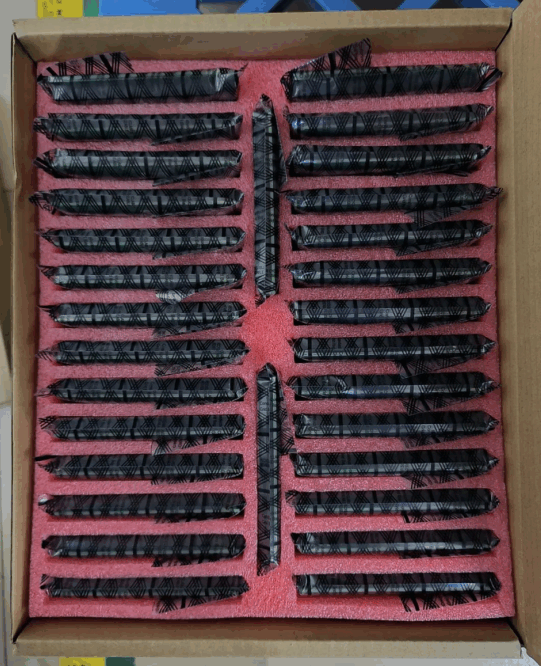

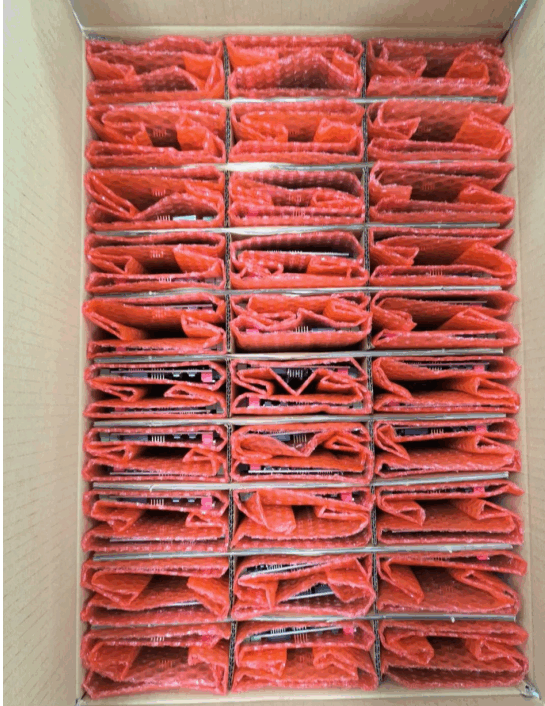

Anti-vibration Cushioning Materials

Use EPE foam, bubble wrap, or custom foam inserts to fill any empty space inside the box, preventing movement during transportation.

When stacking vertically, do not exceed two layers, and insert dividers to prevent crushing or deformation.

PCBA Transportation Packaging

3. Key Measures During Transportation

Short-Distance Transportation: Balancing Efficiency and Protection

Select packaging boxes with high shock resistance and secure circuit boards inside with straps.

Prioritize traceable local logistics to minimize transit time.

Long-Distance Transportation: Comprehensive Monitoring is Essential

Temperature and Humidity Data Logger: Monitor the transportation environment in real-time, ensuring temperature is maintained within a suitable range of 20-25°C and humidity at 40-60% RH.

Multi-Layer Moisture-Proof Packaging: Use a thickened outer corrugated box with anti-static and vacuum-sealed inner layers for dual protection.

Emergency Plan: Develop contingency plans, including alternative routes or insurance coverage, to address extreme weather or delays.

PCBA Transportation Packaging

4.Special Scenario Handling

High-Sensitivity Component Transportation

For chip-intensive or high-frequency circuit boards, use individual tray packaging to prevent component pin collisions, and label the packaging as "Fragile."

Anti-Salt Fog for Sea Transportation

Beyond moisture protection, apply an anti-corrosion coating and use corrosion-resistant aluminum foil bags for packaging.

5. Industry Cases and Lessons

One company once suffered a loss of over one million yuan when a batch of circuit boards was damaged by moisture during transportation due to the use of ordinary bubble wrap. After switching to vacuum anti-static packaging with desiccant, the failure rate dropped to below 0.5%. This illustrates that attention to detail is crucial for success! Conclusion

The transportation packaging of circuit boards is more than just a cost consideration; it's a commitment to product reliability. From anti-static and moisture protection to shock resistance, each step requires careful planning. Partnering with professionals and establishing standardized packaging procedures are essential to ensuring that every circuit board arrives safely at its destination.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108