* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

Currently, various testing technologies are employed in electronic assembly testing, including Manual Visual Inspection (MVI), In-Circuit Testing (ICT), Automatic Optical Inspection (AOI), Automatic X-ray Inspection (AXI), and Functional Testing (FCT).

These testing methods can be categorized based on whether the PCBA board is powered on, leading to two main types: electrical testing technologies and non-electrical testing technologies. Additionally, they can be divided according to whether the PCBA is in contact with the testing equipment, resulting in contact testing and non-contact testing technologies.

Online Testing (ICT)

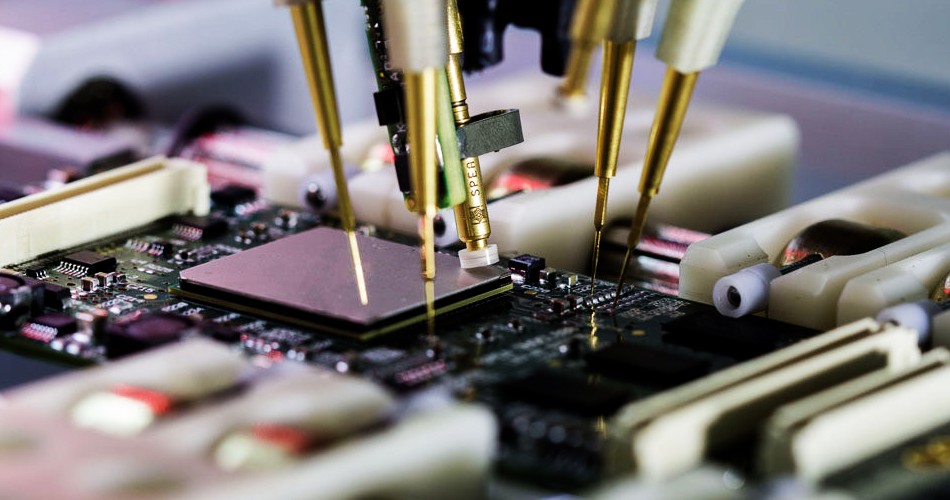

The Online Tester (ICT), also known as a flying probe tester, is a method used to identify production issues and faulty components by checking the electrical performance and connectivity of the assembled PCBA board’s components.

Online Test ICT in PCBA Assembly

During the testing process, a special flying probe contacts the components on the assembled PCBA. It uses hundreds of millivolts and a current of up to 10 mA to conduct isolated tests, allowing for the accurate identification of faults such as missing installations, incorrect installations, deviations in parameter values, solder joint issues, and open or short circuits in various components, including resistors, inductors, capacitors, diodes, transistors, silicon-controlled rectifiers, and integrated circuits. This process precisely locates the faulty components or the points of open or short circuits.

The primary advantage of using a flying probe test is its rapid response to market needs; however, its detection speed is slower, making it suitable for testing samples and small batch orders. If a customer requires a printed sample, the flying probe test can be selected initially, and the needle bed test can be adopted later when the customer places a large order. This approach eliminates the costs associated with producing a needle bed for process changes or order cancellations.

ICT is particularly beneficial for detecting electrical defects, such as abnormal functions or incorrect values of devices. While online testing can effectively reveal various defects and faults during assembly, it cannot fully assess the electrical performance of the PCBA.

Customers' PCB designs need to meet the testability requirements for ICT, which can be challenging due to the diverse needs of PCBA processing customers. Furthermore, as the number of test nodes increases, costs can rise significantly, primarily due to the design and manufacture of the needle bed or flying probes. Challenges arise when the number of nodes exceeds the ICT specifications or when the physical size of the PCBA is not suitable for ICT testing.

The trend towards miniaturization in electronic products has directly resulted in high-density integration of PCBA board designs, reducing the applicability of ICT testing. This shift means production and manufacturing may encounter numerous potential challenges. As a result, PCBA assembly may proceed directly to final inspection, leading to a decline in quality rates, increased repair and fault diagnosis costs, and potential production delays.

Why Choose China PCBA Supplier KSPCBA as Your Online Test ICT Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108