* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

Keywords Integrated:what is FPC flexible circuit, FPC vs rigid-flex PCB, flex PCB manufacturing process, FPC design guide, flexible circuit board materials

Flexible Printed Circuits, or FPCs, are reshaping the world of electronic design with their lightweight, bendable, and space-saving properties. If you've ever wondered what is an FPC or how flexible PCBs work, this comprehensive 9-step guide will walk you through everything from materials to applications.

1. What Is an FPC (Flexible Printed Circuit)?

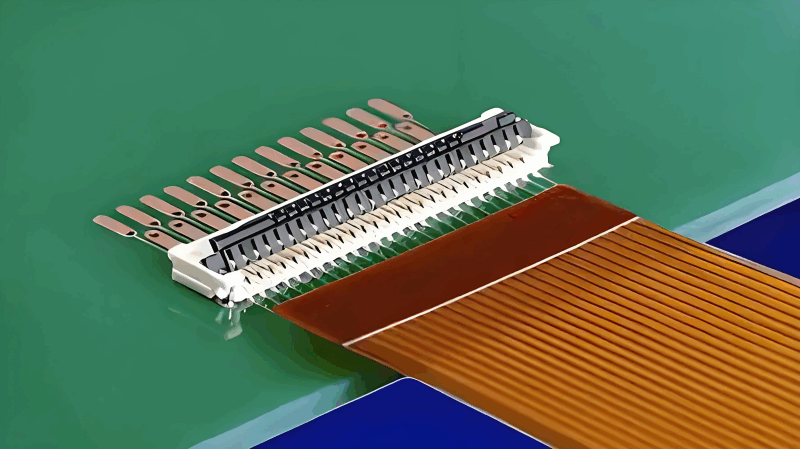

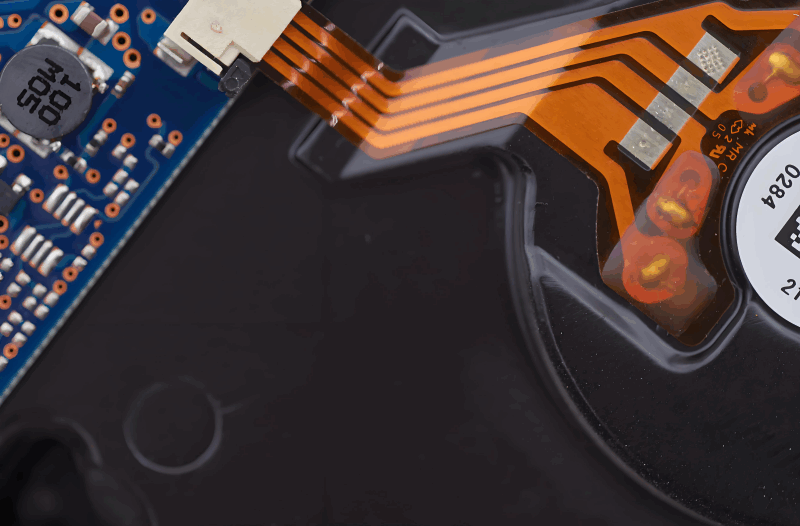

FPC, or Flexible Printed Circuit, is a type of circuit board that can bend, twist, or fold without losing functionality. Unlike rigid PCBs, FPCs are built on flexible substrates like polyimide (PI) or PET, making them ideal for compact, mobile, and dynamic electronic applications.

2. Core Advantages of FPC Over Traditional PCBs

3. Main Types of Flexible PCBs

There are several categories of FPCs based on their layer count and construction:

Each type serves different application needs based on complexity, cost, and performance.

9 Steps to Fully Understand FPC

4. Key Materials Used in FPC Manufacturing

Material selection affects bending performance, heat resistance, and signal stability.

5. The Manufacturing Process of FPC

FPC production involves more precision and flexibility than rigid boards. Typical steps include:

6. Common Applications of FPC

FPCs are widely used in industries requiring miniaturization and mobility:

9 Steps to Fully Understand FPC

7. Design Guidelines for Flex PCB Engineer

To ensure mechanical and electrical reliability:

Proper design dramatically increases FPC lifespan in real-world conditions.

8. FPC vs. Rigid-Flex PCB: What's the Difference?

| Feature | FPC | Rigid-Flex PCB |

| Structure | Fully flexible | Mixed rigid and flexible |

| Cost | Lower | Higher |

| Assembly complexity | Easier | More complex |

| Durability | Less mechanically robust | High durability |

| Application | Simple interconnects | High-end devices (e.g. aerospace, military) |

Choose based on your device structure and mechanical stress levels.

9. Future Trends of Flexible PCBs

As consumer electronics move toward thinner, lighter, and more dynamic form factors, FPC demand continues to grow. Key future trends include:

Manufacturers and engineers investing in flex PCB technology are positioning for the next generation of innovation.

Final Thoughts

FPCs are no longer a niche solution — they are a core enabler of modern electronics. Understanding their structure, benefits, and applications is crucial for engineers, designers, and product developers alike.

If you're looking for FPC prototyping or volume manufacturing, our engineering team provides one-stop flex PCB solutions, from design consulting to assembly and testing.

Contact us today to bring your flexible electronic ideas to life!

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108