* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

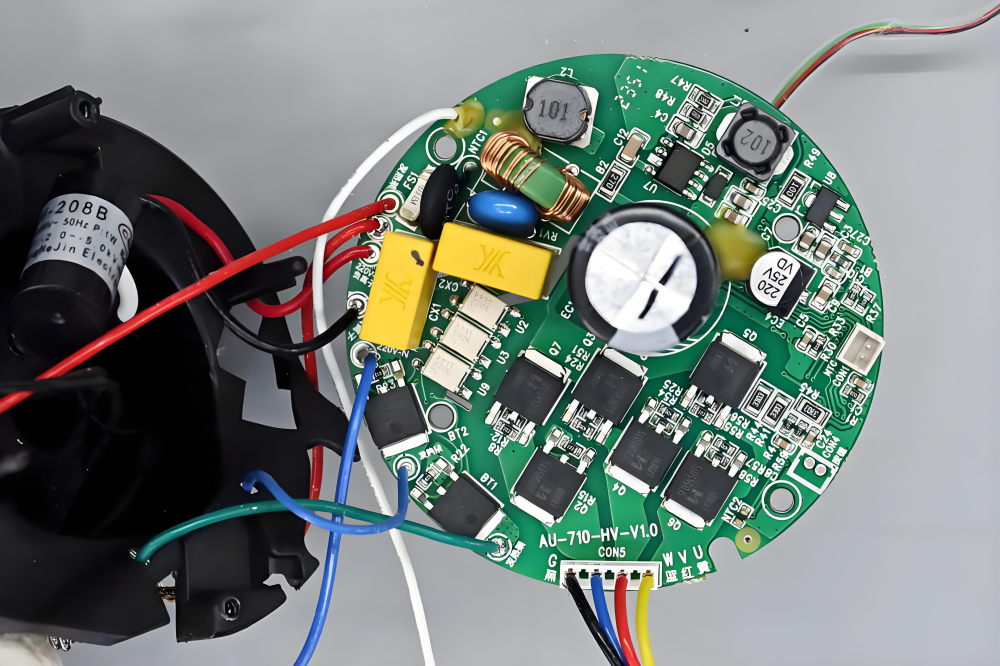

This circuit board manufacturer is a professional PCBA chip processor with extensive production and processing experience. Below are the essential requirements for varistors in PCBA design:

1. Operating and Storage Temperature

The operating temperature of the circuit must remain within the range specified in the product specifications. After mounting, the storage temperature while the circuit is non-operational should also be kept within the specified service temperature range. Avoid exposure to temperatures exceeding the maximum operating temperature indicated in the specifications.

2. Applied Voltage

The voltage applied between the varistor terminals must remain below the maximum allowable circuit voltage. Incorrect usage can lead to product failure, short circuits, and potential overheating. Even when the voltage is below the rated voltage, it is critical to evaluate the varistor's reliability when high-frequency or pulse voltages are continuously applied.

3. Element Heating

The surface temperature of the varistor should remain below the maximum working temperature specified in the product specifications. It is important to consider the temperature rise induced by the element itself. Ensure that the temperature rise of the varistor due to circuit conditions is assessed under the actual working conditions of the equipment.

Design Requirements of Varistor in PCBA Design

4. Usage Limitations

Varistors should not be used in the following environments:

- Areas with water or saltwater

- Locations prone to condensation

- Environments containing corrosive gases (e.g., hydrogen sulfide, sulfurous acid, ammonia)

- Areas subjected to vibration or impact that exceed the limits specified in the product specifications

5. Circuit Board Selection

The durability of alumina circuit boards may be compromised by thermal shock (temperature cycling). Therefore, it is crucial to confirm whether the selected circuit board impacts the product's reliability.

6. Pad Size Configuration

The more solder applied, the greater the pressure on the varistor, which can lead to quality issues such as surface cracks. When designing the PCB pads, ensure that the shape and size are appropriate for the amount of solder used. Additionally, keep the sizes of left and right pads symmetrical. If the solder amounts are unequal, the side with more solder will solidify more slowly, which can result in stress and cracking on the side with less solder.

7. Component Configuration

After the varistor is welded and installed on the circuit board, or if the circuit board is subjected to bending during operation, there is a risk of breakage. Therefore, when configuring components, it is vital to consider the bending strength of the circuit board and avoid applying excessive pressure.

By adhering to these guidelines, you can ensure the reliability and performance of varistors in your PCBA designs.

Why Choose China PCBA Supplier KSPCBA as Your PCBA Design Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108