* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Home | Events | PCB | About Us | News | Contact Us

In the competitive landscape of electronics manufacturing, a seemingly ordinary PCBA board carries the lifeblood of your product. As it journeys from production lines to global customers, its flawless operation isn’t just about user experience—it determines your brand’s survival. While many manufacturers treat ICT (In-Circuit Test) and FCT (Functional Test) as golden standards, industry leaders know better: these two basic checkpoints alone cannot build an impregnable quality fortress. Here, we unveil the critical yet often overlooked tests that construct a multi-dimensional shield for premium electronics.

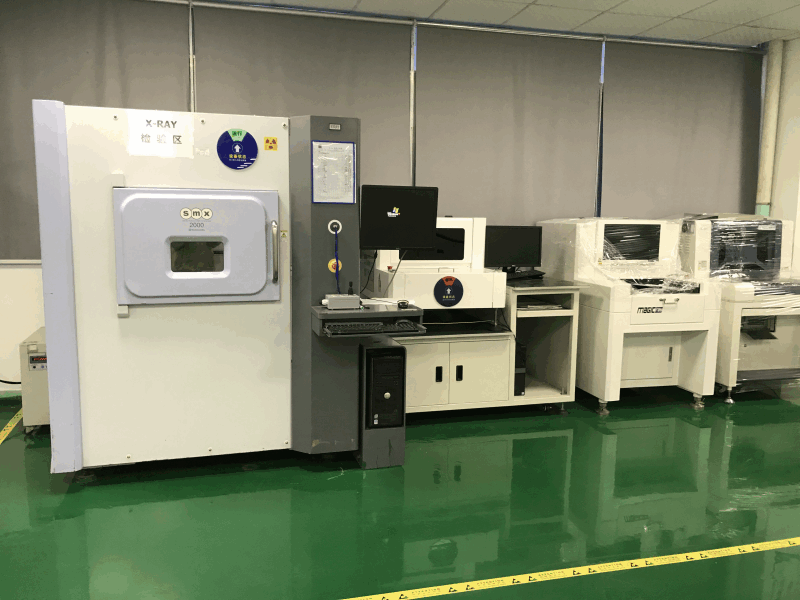

Vision Systems: AOI & AXI – The "Microscope" and "X-Ray" for Solder Defects

AOI (Automated Optical Inspection) acts as a tireless precision inspector. Using high-speed multi-angle cameras, it scans solder joints, component misalignment, reversed polarity, and missing parts at 0.01mm resolution.

Real Impact: A telecom equipment manufacturer reduced SMT defects from 850 ppm to 120 ppm after AOI implementation, with 300% efficiency gains for 01005 micro-components.

AXI (Automated X-ray Inspection) penetrates surfaces to expose hidden killers:

Revealing the Invisible: Accurately detects solder bridges, voids (>15% volume), cold joints, and BGA/LGA defects. An automotive client avoided vehicle recalls by catching 0.3mm-pitch BGA bridges via AXI.

AXI

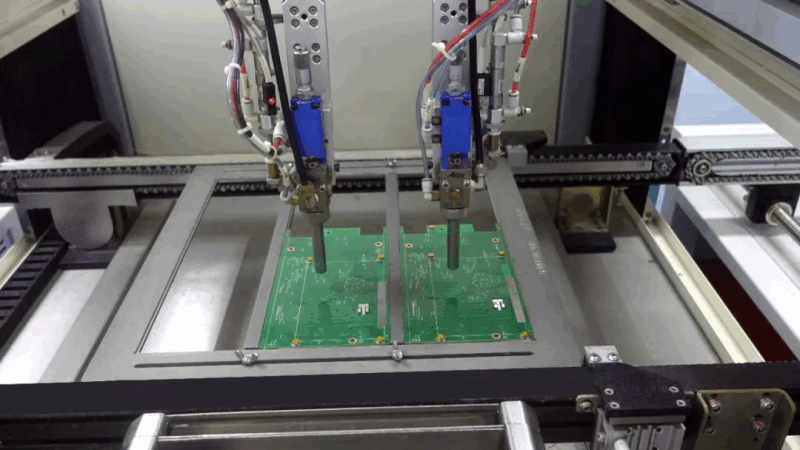

Flying Probe Test: The Agile "Special Forces" for Electrical Validation

When traditional ICT struggles with fixture costs and slow changeovers, Flying Probe Testing becomes the savior for low-volume/high-mix production:

Precision Access: 4/6-axis probes reach test points in dense layouts unreachable by ICT.

Case Study: A medical device developer accelerated time-to-market by 40% using flying probes to validate 5 design iterations in 24 hours.

Burn-In Testing: Eliminating "Infant Mortality" Failures

Powering PCBAs under extended high-temperature operation (e.g., 48h at 125°C) accelerates early-life "bathtub curve" failures:

ROI Evidence: A server manufacturer found that 1% burn-in fallout prevented millions in warranty costs.

Smart Evolution: AI-driven current/temperature monitoring predicts failures (e.g., capacitor degradation).

Boundary Scan (JTAG): The "Neurologist" for Complex Digital Circuits

For high-density designs (CPU/FPGA), JTAG leverages test access ports (TAP) to:

Validate interconnects and locate PCB micro-shorts/opens

Verify logic states without external stimuli

Efficiency Breakthrough: An industrial control maker replaced 30% of FCT cases with JTAG, cutting test time by 50%.

X-RAY

High-Speed Signal Testing: The "Traffic Controller" for Data Highways

At speeds >5Gbps (PCIe 4.0/USB4/DDR5), signal integrity becomes non-negotiable:

Eye Diagram Analysis: Ensures margin compliance (e.g., eye height >100mV)

TDR Impedance Testing: Locates impedance discontinuities (>±10% tolerance)

Costly Lesson: A GPU vendor lost $2M due to display flickering from skipped impedance checks.

Conformal Coating Inspection: The "Invisible Shield" Against Corrosion

In humid/salty environments, coating integrity dictates product lifespan:

Thickness Verification: Ultrasonic gauges enforce 25-75μm IPC standards

Coverage Mapping: UV fluorescence detects micron-level voids

Compliance Critical: Maritime equipment manufacturers prevent corrosion failures through 100% IPC-CC-830B coating checks.

PCBA

Why Industry Leaders Invest in "Extra" Tests?

Data from a top-3 global telecom OEM reveals:

"Every $1 in testing saves $23 in field costs"

ESS + Burn-In screened 0.3% early failures, reducing annual warranty spend by $8.7M

High-speed testing eliminated 100% of HDMI compatibility returns

In elite manufacturing, testing isn’t a cost center—it’s the engine of brand premium. When your PCBA survives AOI’s sharp eyes, X-ray’s deep scrutiny, -55°C thermal torture, and 5Gbps signal trials, it carries more than components—it delivers trust and market dominance.

True quality champions never compromise on testing. Because every skipped check is a landmine in your future; every fully validated PCBA silently proclaims: This is the manufacturing creed of Industry 4.0.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108