* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

China One-stop Electronic Printed Circuit Board

The process of attaching electronic components to a printed circuit board (PCB) to create a PCBA—a module that may be assembled with additional components to create an end product or system—is known as PCB assembly.

Electronic assembly services, circuit board assembly services, and circuit card assembly services are other names for PCB assembly services.

The electronics industry relies heavily on PCB assembly services because all electronic devices require PCB assembly, which is performed by PCB assembly businesses, OEMs, component suppliers, and PCB material suppliers.

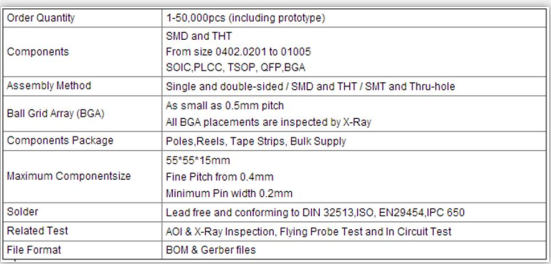

PCB assembly services include:

PCB fabrication: From prototypes to bulk fabrication, KSPCBA offers PCB manufacturing services for all types of PCBs, including FR4, flexible, rigid-flex, ceramic, MCPCBs, etc. Sending your Gerber is all that is required.

SMT (surface-mount technology) assembly: SMT is a method of automatic PCB assembly. It consists of reflow soldering, x-ray inspection, visual inspection, solder paste printing, SPI (solder paste inspection), inserting SMDs, and AOI (automated optical inspection).

THT (through-hole technology) assembly: The PCB assembly method THT is semi-autonomous. After the THT components are manually or mechanically placed through holes, the PCBA is wave-soldered and heated. To guarantee soldering quality, KSPCBA uses German Ersa selective wave soldering machines.

FAI (first article inspection): The PCB assembly FAI is provided by KSPCBA. We produce five PCBAs, and we choose one at random to examine each component. Following that, a report on FAI is created for evaluation. We won't begin mass-producing PCBAs unless you give your okay.

Functional testing: This self-test is power-on. To test their functionality, the PCBAs are placed one at a time on a jig. The functional test is free for large-scale PCBA manufacture at KSPCBA and costs just $0.075 per piece.

Why Choose China PCBA Supplier KSPCBA as Your China One-stop Electronic Printed Circuit Board Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

Fully automatic, high precision SMT and test equipment.

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108