* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Printed circuit boards can be classified into four main types: rigid, flexible, semi-flexible, and rigid-flexible. The key factor determining the type of PCB is the substrate material used. Among these types, rigid boards are the most common and straightforward to manufacture with multiple layers. When a rigid board consists of four or more conductive layers, it is referred to as a multilayer rigid PCB. These layers are separated by an insulating material, forming a single integrated unit.

Multilayer Rigid PCBs

Three main types of vias are used to establish connections between the layers in a multilayer rigid PCB: buried vias, blind vias, and through-hole vias. This structure typically consists of external layers located at the top and bottom, which function as single-sided boards. The internal layers, on the other hand, act as double-sided boards and are interconnected. Some of these layers may serve specific purposes such as power planes or ground planes. Depending on the requirements of industrial projects and design specifications, rigid multilayer PCBs can have many layers, ranging from a few to over a hundred. However, it is more common to find multilayer PCBs with four to eight layers in various devices, such as smartphones, where the circuitry is often configured on 12-layer boards. In these applications, the inner core of multilayer rigid printed circuit boards comprises the core layer, prepreg, intermediate layer, and inner layer.

Flex Circuit Board

Flexible PCB is a kind of flexible circuit board with the simplest structure, not only can be used alone but also can be connected to other circuit boards, used in communications, security, medical, industrial control, home appliances, and digital products, etc. Flexible PCB are generally divided into single-layer boards, double-layer boards, multi-layer boards. Flex PCB have numerous advantages over rigid boards, including space-saving, lightweight construction, excellent signal integrity, and the ability to conform to non-planar surfaces. They are commonly used in industries such as consumer electronics, automotive, medical devices, aerospace, and more.We aim to deliver high-quality Flex PCB that meet industry standards and customer specifications. Their services may include prototype development, volume production, component assembly, and quality assurance.

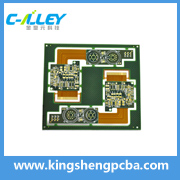

Rigid-flexible Circuit Board

The birth and development of FPC and PCB has given birth to the new product of Rigid-Flex PCB.The Rigid-Flex PCB is rigid pcb and flexible pcb,through pressing and other processes, according to the relevant technological requirements combined together,formed with FPC characteristics and PCB characteristics of the circuit board.

The characteristics of Rigid-Flex PCB determine its application field covers all application fields of FPC and PCB, such as communication, smart home, optoelectronics, industrial control, medical equipment, automotive and consumer electronics.

Why Choose China PCBA Supplier KSPCBA as Your Multilayers Rigid, Flex, Rigid-flexible Circuit Board Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

Fully automatic, high precision SMT and test equipment.

Comprehensive testing include AOI, X-Ray, ICT, software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108