* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

What is behind the abbreviations OEM?

There are two common interpretations of what it meant to be an original equipment manufacturer. The most popular concept presumably has to do with a producer who sells its own goods. We may conclude that this notion represents an OEM entity with a strong brand and a commanding presence in the market. Meopta-optics, Foxconn CZ, and Průša are 3D printers. Businesses that we don't need to introduce in more detail. These producers are included in the OEM group.

One meaning of the acronym OEM, which is more prevalent in our context, is a business that provides full product realization as a service to outside parties. The business approach is predicated on expertise, creativity, and internal project development. The OEM often retains any proprietary or patent rights included in the development. Even these businesses, though, now outsource a sizable portion of the work. Therefore, one may argue that the letter M in the name is a little out of date.

The PCBA OEM model is a development direction of the current electronic manufacturing and processing industry. Compared with traditional SMT processing, this article will give you a detailed analysis of its specific advantages.

1. Cut expenses associated with business administration and procedures.

In the conventional paradigm, buying departments receive the Gerber file and BOM list from electronic engineers, who also frequently create the circuit diagram. Based on the Gerber file and BOM list that the engineer provides, the purchasing department locates the relevant PCB board maker and electronic material supplier, and from there it locates SMT. The entire procedure is labor-intensive and requires a lot of material resources. Selecting the PCBA OEM model spares you money on procurement and material management because all you have to do is submit the PCBA processing manufacturer the Gerber file and BOM list. Cost, time, labor, and location expenses. It's also simpler to oversee the procedure.

2. Benefits of using procurement channels to cut expenses.

Facilities that process PCBAs frequently benefit from consolidated procurement and a whole supply chain. There are more guarantees regarding the pricing, delivery time, and quality of different materials. When required, you can prepare items ahead of time to save money and time by reducing the possibility that you won't have enough inventory.

3. The product quality is assured and the quality management system is flawless.

A comprehensive quality management system, comprising DFM manufacturability inspection, NPI new product introduction meeting, IQC incoming material inspection, IPQC process inspection, FAI first article inspection, and OQA factory inspection, is in place at the PCBA factory to regulate the quality of the products. These many inspections are crucial to the quality assurance of the product and are essential for early identification, early improvement, and early resolution. In order to better serve consumers, the PCBA plant will also strengthen its hard power at the same time by getting certifications for its ISO9001:2015 quality management system, ISO13485 medical certification, IATF16949 certification, SGS certification, and other certifications.

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

Fully automatic, high precision SMT and test equipment.

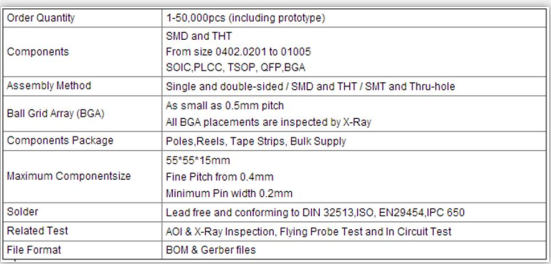

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108