* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

What exactly is a PCB redesign?

Verifying the production documentation that already exists, converting it into a new development environment, confirming that all components are available, adjusting schematics and layout, and verifying a new design are all part of the intricate process of PCB redesign. The requirement for increased availability of specific components is the most frequent cause for redesigns. It's possible that the necessary component won't be available for a while. Additionally, there can be circumstances where a particular component's end of life (also known as EOL, or End of Life), or NRND, Not Recommended for New Design, is drawing near. These days, it's not uncommon to find integrated circuits unavailable. Numerous makers of electronic components were compelled to curtail their production capacity due to the epidemic.

There are four important reasons for choosing kingshengPCBA to resign or copy PCB boards.

1. Current technology and components

Making a direct copy of an existing circuit board limits you to using the technologies available when it was first designed – which means you’re stuck using older systems and obsolete, hard-to-find components.

Reverse engineering the circuit board retains 100% functionality while reducing costs by using readily available, cheaper, easier-to-handle parts and processes.

2. Original plans in a universal format

Making a direct copy of a circuit board may not be possible, particularly with multi-layered PCBs. Some people X-ray PCBs or actually abrade the board, layer-by-layer, to make photocopies. These approaches, however, introduce errors that can impair functionality.

Reverse engineering the PCB gives you a first-generation set of plans no matter how complex the circuit board is.

3.No intellectual property conflicts

There may be copyright issues to circuit board cloning that could expose your organization to liability if you don’t own all the intellectual property rights.

In contrast, according to U.S. copyright law, the result of reverse engineering is not a copy. Although the new PCB is functionally identical to the old one, there are enough differences, including current trace routing and updated component specifications, to make it an original piece of work.

4. The ability to move forward

Unlike simply copying the circuit board, reverse engineering reveals how the circuit board does what it does. You get all-new manufacturing files, including schematics, Gerber files, and drill files for each layer. That enables you or your design team to improve the product or add capabilities going forward.

We’ve done numerous projects in which an existing circuit board was simultaneously reverse-engineered and upgraded. We can even build pre-production prototypes for testing.

We specialize in redesigning and updating your existing PCB. Send us your existing PCB with all (still present) drawings, part lists, files, and your wishes. We take care that you will receive a reliable PCB with the most modern components, which works without disturbance. This new PCB complies with the latest production standards, which results in decreasing costs for labor and purchasing components.

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

Fully automatic, high precision SMT and test equipment.

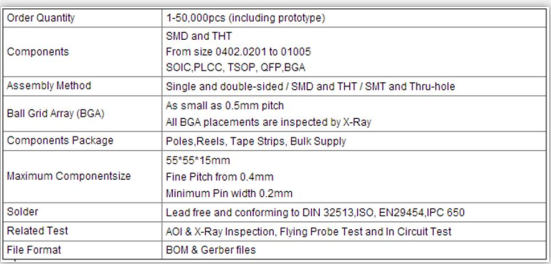

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108