* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

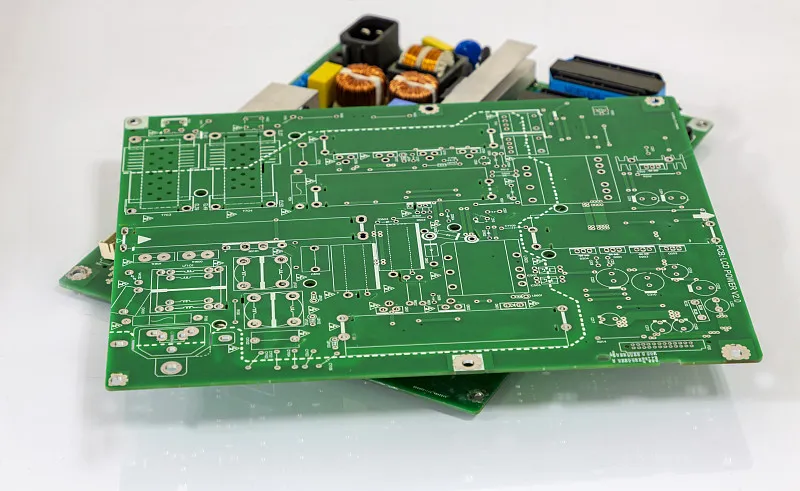

China PCB assembly

SHEN ZHEN Kingsheng PCBA TECH.Co,.Ltd. since its establishment in 2008 has kept providing One-stop PCB Assembly Service and Electronics Manufacturing Service (EMS) in Bao’an District Shenzhen, China for global customers. As ISO 9001, UL, CSA, and CCC certified manufacturer, we offer flexible, cost-effective and high-quality EMS solutions for printed circuit board assembly (PCBA) and complete product assembly through advanced manufacturing technologies and facilities. We are leading PCB assembly manufacturer and printed circuit boards supplier in China. Due to the special and high grade requirements of automotive regulations, it has also contributed to the formation of the company's quality DNA. Over the years, we have been adhering to the business philosophy of quality as the root and service as the soul, providing high-quality EMS for global customers.

SMT

Surface mount technology (SMT) is an aspect of electronic assembly where electronic components, also called surface mount devices (SMD), are directly mounted onto the surface of a printed circuit board (PCB). Because of its cost and quality efficiency, SMT has become highly sought after in the industry.

Reflow

Solder reflow is a critical process in the electronics industry, primarily used to attach surface-mount components to printed circuit boards (PCBs). It involves applying solder paste to specific locations on a PCB, placing the components on the paste, and then heating the assembly in a reflow oven. The solder paste melts, forming a reliable electrical and mechanical connection between the component and the PCB. The quality of these connections has a significant impact on the performance and reliability of the final electronic product.

DIP

Dual in-line package (DIP) is the most common through-hole IC package in the PCB electronic component packaging process, abbreviated as DIP or DIL. DIP packages are typically melt-molded from an opaque epoxy resin with a lead frame supporting the device chip. And provide connecting pins extending vertically out of the rectangular plastic housing. Silver, gold or tin plating is optional around the parallel metal pins (pin headers) on both sides of the IC.

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

Fully automatic, high precision SMT and test equipment.

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108