* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

What is an High Power inverter pcb board?

Transforming direct current (DC) into alternating current (AC) is the main function of an inverter circuit board. Since many of the appliances we use on a daily basis—like computers, refrigerators, and air conditioners—require AC power, this conversion is necessary.

Inverters are electronic devices that convert DC (direct current) electricity into AC (alternating current) electricity, making it usable for various appliances and electronics. An inverter typically consists of several components, but the system’s heart is the printed circuit board (PCB) inverter.

An electrically powered device that changes direct current (DC) power into alternating current (AC) power is called a printed circuit board (PCB) inverter. It is an important part of many electrical systems and is essential to the operation of residential and commercial equipment by supplying AC power. Transistors and diodes are utilized by the PCB inverter to transform DC electricity from solar panels or batteries into AC power that may be used for a variety of purposes.

Phone charger PCBA with Power Supply

A Phone charger is a kind of device that efficiently charges a compatible mobile phone or cellphone when that is kept nearby. The wireless charger can charge the device with no physical contact and just by transferring wireless current having high frequencies.

How does PCB work in the Phone charger?

In addition to electrically connecting the electronic components via signal traces, conductive pathways, or tracks that are finely etched from copper sheets laminated on the surface of a non-conductive substrate, a printed circuit board, or PCB for short, offers mechanical support.

In order to split the power to the mobile phone module, the power transmitter circuit must first be connected to the main connection supply for a phone charger. It is imperative that the transmitter circuit be designed correctly, using Tesla's well-known pancake coil configuration.

The role of PCB then comes into play. Very carefully and precisely, a smaller configuration of the pancake coil to be utilized is etched and wired over the PCB. The PCB layout shapes the design into a compact form and gets it ready for seamless operation. The arrangement can take the form of a square or an oval.

Therefore, PCB is necessary for developing electronic circuits in an efficient manner. Both manual and automatic PCB design creation are available. PCBs are among the fundamental parts of electronic equipment. A smart PCB design lessens the chances of errors and the possibilities of electrical hazards such as short circuits. One of the key discoveries that revolutionized and greatly enhanced the field of electrical technology is the printed circuit board (PCB).

Why Choose China PCBA Supplier KSPCBA as Your Customized High Power Inverter PCB Circuit Board Phone charger PCBA with Power Supply Manufacturer?

– Experienced and skilled team

– State-of-the-art equipment

– Strict quality control

– Excellent customer service

– Competitive price

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

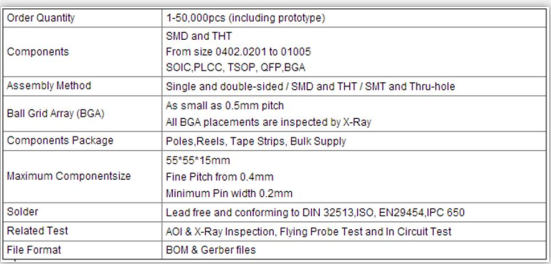

Fully automatic, high precision SMT and test equipment.

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108