* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Due to consumer demand for increasingly sophisticated and high-performing iPhone/Android Mobile Phone, the smartphone industry has undergone significant transformation in recent years. To satisfy these requirements, the printed circuit board (PCB), which is at the core of these devices, must also change. Our Advanced Smartphone PCB can help in this situation.

Our Advanced Smartphone PCB motherboard is designed to meet the demanding requirements of today’s high-performance smartphones. It is made of high-quality materials and manufactured using state-of-the-art technology to ensure optimal performance and reliability. This PCB is the perfect solution for smartphone manufacturers looking to enhance the performance and capabilities of their devices.

The progressive increase of features integrated into the latest generation mobile devices is imposing ever more stringent requirements on printed circuit board design. Wi-Fi and Bluetooth connectivity, support for 4G and 5G mobile networks, and integration with an ever-increasing number of sensors represent unprecedented technological challenges for electronic designers. Mobile devices, starting with smartphones, are evolving towards greater intelligence, miniaturization, and multifunctionality, requiring increasingly complex printed circuit boards capable of supporting these requests (the trend imposed by the market is to have increasingly thinner devices, with thicknesses normally less than one centimeter).

Numerous high-performance smartphones, such as high-end models and gaming smartphones, can be equipped with this Advanced iPhone/Android Mobile Phone PCB motherboard. It is perfect for modern smartphones because of its small size and high-density component integration. In order to satisfy customer demands, modern smartphones need increasingly sophisticated and small electronics.

Technical challenges

Current smartphone development trends necessitate the use of rigid-flex PCBs for auxiliary boards and multilayer printed circuits (PLCs) with fewer layers for the motherboard, which can be built of ten or more layers. The growing popularity of SiP (System-in-Package) components and multi-core SoCs (System-on-Chip), which are also available with 64-bit architecture, along with the decrease in pin spacing from 0.4mm to 0.35mm, are likely to offset, if not actually cause, the increase in layer count.

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

Fully automatic, high precision SMT and test equipment.

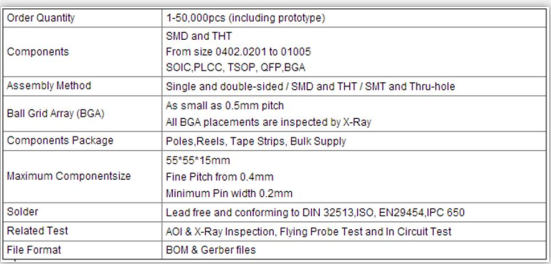

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108