* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

Wireless Security Camera PCBA Assembly Description

In the modern world, security has taken on utmost importance, which has raised demand for surveillance systems. Camera PCBs are among the crucial parts of these systems. The core of a security camera is called a camera PCB, or printed circuit board. It acts as the focal point for all of the electrical parts needed to take, process, and send pictures or movies. PCBs for wireless security cameras are necessary to transform the real world into digital information. They contain parts like processors, memory, and image sensors, all of which are essential for capturing high-quality security footage.

Image Sensors

The camera's eyes are image sensors. The foundation of the pictures or films is created by them as they take in incoming light and transform it into electrical impulses.

Processors and Memory

While memory temporarily stores the data, processors handle the computation needed for image processing. For the camera to operate smoothly, both are essential.

Control of Power

Sustained monitoring requires effective power management. Power management components are integrated onto camera PCBs to guarantee dependability.

Ports and Connectors

The camera can link with other devices and networks thanks to connectors and ports, which makes control and data transfer easier.

Applications of Indoor Security

Camera PCBs are widely used in indoor security applications, including office surveillance, retail establishments, and home security systems. They are perfect for monitoring enclosed locations because of their small size and high resolution capabilities.

Applications for Outdoor Security

Camera PCBs are made to survive hard weather conditions in outside security applications. Ruggedness and dependability are essential, and they are frequently utilized in industrial facilities, traffic monitoring systems, and outside surveillance cameras.

Technological Developments in Camera PCB

Camera PCB technology is a sector that is always changing. The creation of increasingly complex and powerful surveillance systems is being propelled by developments in image sensor technology, downsizing, and power efficiency.

Problems with the Manufacturing of Camera PCBs

The problems of manufacturing camera PCBs include maintaining good quality, controlling production costs, and guaranteeing interoperability with different camera designs.

Upcoming Patterns

We may anticipate that Camera PCBs will play an even more crucial role in security systems as technology develops. Future developments could see an increase in wireless communication, better energy efficiency, and more AI capabilities.

The unsung heroes of the surveillance systems that protect us are the camera PCBs. Complex procedures are used in their assembly and production to guarantee that they satisfy the requirements of both interior and outdoor security applications. Camera PCBs will become ever more important in determining the direction of security as technology develops.

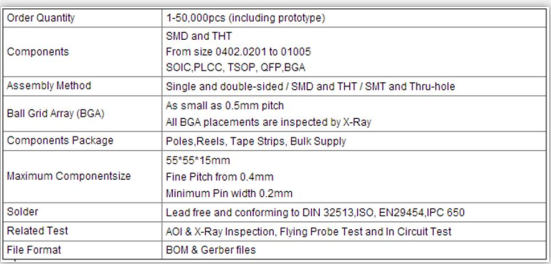

We offer professional OEM/ODM PCB manufacturing & PCB assembly services for your different projects, from small electronics to large equipment, covering various kinds of fields, such as Home Appliances, Medical, Automotive, Military, Communication, Consumer Electronics, Robotics, Lighting, Sensor, Industrial Equipment, etc.

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

Fully automatic, high precision SMT and test equipment.

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108