* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

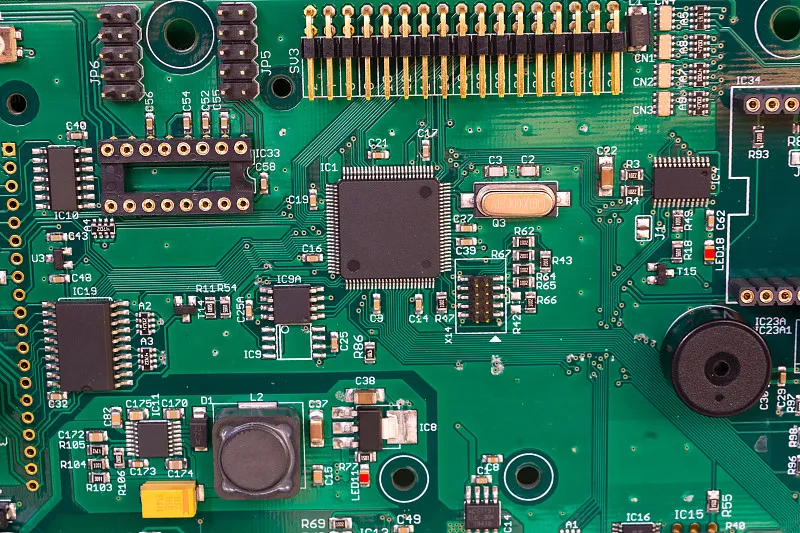

China PCB Copy

In the electronic industry, PCB cloning, also known as PCB duplication, is the process of making a duplicate of the original PCB by employing reverse engineering techniques. This is helpful if you need to make new items using the same printed circuit board design or if you have different variants of the same PCB. To reuse components from an existing printed circuit board for a different project, you can alternatively clone the PCB. We will provide you with vital knowledge on all the aspects of cloning printed circuit boards, even if you are not experienced with electronics.

PCB Reverse

Reverse engineering is used in many different industries, but it is particularly well-liked by people who work with printed circuit boards (PCBs). Reverse engineering PCBs can provide vital knowledge about their design and operation, which can be used to upgrade outdated circuit boards, repair damaged ones, or create a less expensive substitute for a rival product. You can fully comprehend how your PCBs function and enjoy a host of advantages by learning how to reverse engineer PCBs.

OEM

An Original Equipment Manufacturer (OEM) makes components of another company's products. An OEM component might be a part, a subsystem, or software. Examples include operating systems (OS) and microprocessors in computers. Typically, the computer manufacturer makes neither the microprocessor nor the OS.

ODM

The advantage of ODM is that it spares importers the need to invest millions of dollars into research and development in order to create a new product from scratch. Why reinvent the wheel when you can just improve one that already exists? And by eliminating or vastly reducing the expense of product development, importers can focus more on marketing strategies. The disadvantage of ODM is that it can be more difficult to differentiate your product from competitors’ products that are manufactured according to the same design. Although ODM requires less start-up capital, price competition tends to be steeper, resulting in slimmer profit margins. For example, a customer looking to purchase an ODM laser pointer is more likely to choose based on price than based on differences in color or brand. To really differentiate your ODM product from the others on the market, while still remaining competitive price wise, can require a significant amount of creativity.

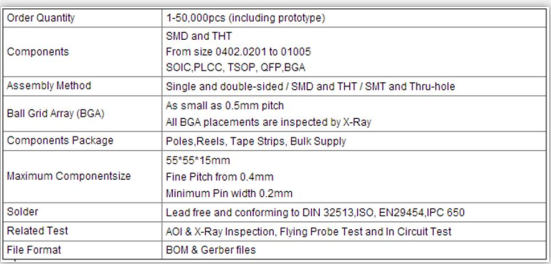

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

Fully automatic, high precision SMT and test equipment.

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108