* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

An essential step in the production of electronic devices is EMS PCB assembly. To construct a working electronic product, electronic components are soldered onto a printed circuit board (PCB). Numerous industries, including telecommunications, medical devices, automotive, and aerospace, use EMS PCB assembly.

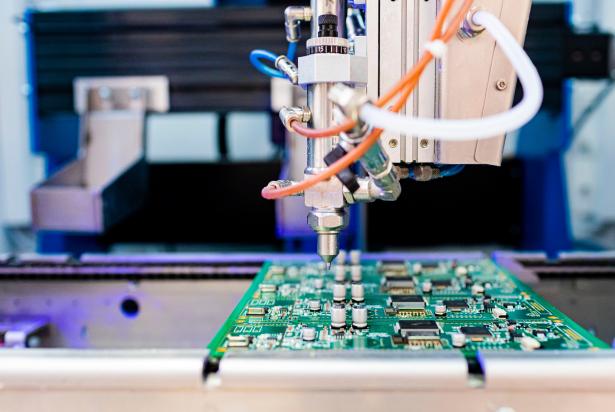

EMS PCB assembly is a multi-step process that includes soldering, component placement, PCB manufacture, and testing. PCB fabrication is the process of producing the board with certain tools and materials after designing the PCB layout. Accurately placing the electronic components on the PCB is known as component placement. The technique of fusing the components onto the PCB with a soldering iron or reflow oven is called soldering. Lastly, testing is done to make sure the product is operating as intended.

EMS Electronic Manufacturing Services or PCB Assembly The process of integrating electrical components onto a printed circuit board (PCB) using both automated and manual procedures is known as PCB assembly. EMS providers offer a variety of services, such as PCB design, prototyping, testing, and production.

Placing electrical components on the PCB, soldering them in place, and connecting them via conductive traces on the board are the steps in the PCB assembly process. To make sure that the parts are correctly positioned, linked, and operating, this process necessitates accuracy and precision.

Numerous industries, including the automotive, aerospace, medical device, and telecommunications sectors, use EMS PCB assembly. Additionally, it is utilized in consumer devices including game consoles, computers, and cellphones.

To satisfy the demands of their clients, EMS providers provide a range of services. These services include consignment assembly, in which the customer supplies the components and the EMS firm performs the assembly, and turnkey assembly, in which the EMS provider manages every step of the assembly process.

All things considered, the EMS PCB Assembly process is essential to the production of electronic products. To make sure that the parts are correctly put together and operate, skill and accuracy are needed.

All things considered, the EMS PCB assembly process is a precise and intricate procedure that calls for specific tools and knowledge. Companies may make sure that the highest quality requirements are met in the manufacturing of their electronic products by collaborating with an experienced EMS supplier.

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

KingshengPCBA Printed circuit boards assembly produced up to100% in-house and 5years warranty

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

Fully automatic, high precision SMT and test equipment.

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108