* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

It will be helpful to look at the definition of OEMs and understand what they stand for and the kinds of offerings they make before we look at some of the strategies and procedures used by OEM PCB makers for the best PCB Assembly.

Original Equipment Manufacturer, or OEM for short, is a business that produces items that are subsequently utilized as parts in the products of another business that sells the final goods to the customer. An OEM contracts out the production of componentry for electrical products. This enables the other printed circuit board manufacturer to concentrate on its primary competencies and workflows. Therefore, the OEM PCB maker has the necessary skills and knowledge to produce innovative, state-of-the-art PCBs. Equipped with industry knowledge, the OEM PCB maker makes sure that the finished product lives up to its reputation and that expensive errors are avoided that could damage the company's standing.

The PCB manufacturing firm makes sure they don't have to increase capacity or suffer more costs in areas that aren't their specialty by employing the OEM's services.

For your various projects, ranging from tiny electronics to large equipment, we provide expert OEM/ODM PCB manufacturing & PCB assembly services. Our services cover a wide range of industries, including home appliances, medical, automotive, military, communication, consumer electronics, robotics, lighting, sensors, and industrial equipment.

IBE can offer a variety of PCB manufacturing & PCB assembly services, from prototyping through production and repair. A variety of printed circuit boards can be designed, prototyped, assembled, and managed supply chained as part of PCB assembly services.

We also offer X-ray inspection, automated optical inspection, in-circuit testing (ICT), BGA reworking, Box Build assembly, and many other services. Our manufactured PCB assemblies are compatible with RoHS regulations and adhere to all relevant industry requirements.

How can we make high quality PCBA products?

Strict incoming material inspection control and management.

KingshengPCBA offers surface mount technology like AOI & X-RAY Inspection and 0201 chip replacement.

Never change BOM indicated material brand without customer’s permission.

Standard Operation Procedure

PCB will be baked in the oven machine in advance.

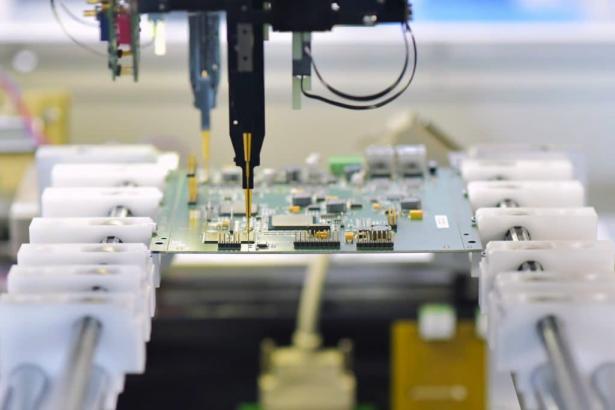

Fully automatic, high precision SMT and test equipment.

Comprehensive testing include AOI,X-Ray,ICT,software burning according to different PCBAs.

Strict quality management system.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108