* On your first PCB Assembly order!

* Up to $300 discount

Ultrasonic PCBA cleaning is a process of removing contaminants or unwanted residues from the surface of Printed Circuit Board Assemblies (PCBA) using high-frequency sound waves. This process uses an Ultrasonic cleaning machine that produces high-frequency sound waves in a cleaning solution to create tiny bubbles that implode and produce a scrubbing action that removes contaminants.

The sound waves produced by the Ultrasonic cleaning machine vibrate through the cleaning solution, creating pressure changes that cause the cleaning solution to penetrate the hard-to-reach corners and gaps of the PCBA. The energy released by these bubbles agitates the cleaning solution, which then loosens and removes contaminants from the surface of the PCBA.

Ultrasonic PCBA cleaning is a non-destructive and environmentally friendly process that does not use harsh chemicals or abrasive materials to clean the surface of the PCBA. It is particularly useful in cleaning PCBA with fine-pitch components like Ball Grid Arrays (BGA), Chip Scale Packages (CSP), or other small components that are sensitive to traditional cleaning methods.

The Ultrasonic cleaning machine used in this process can be programmed to control the frequency, duration, and intensity of the sound waves, making it highly customized to specific PCBA and cleaning requirements. Overall, Ultrasonic PCBA cleaning is an effective method for cleaning PCBA, improving quality, and ensuring optimal performance and longevity of electronic devices.

Kingsheng's ultrasonic cleaning service provides a reliable and cost-effective solution for customers who require high-quality and well-cleaned components and PCB for their electronic products.

Kingsheng uses state-of-the-art ultrasonic cleaning equipment that provides thorough and consistent cleaning results.

They offer customized cleaning solutions tailored to meet the specific needs of each customer, including different frequencies, cleaning fluids, and cleaning cycles.

Kingsheng conducts thorough quality control checks to ensure that all components and PCB are cleaned to the required standard.

Ultrasonic cleaning is an environmentally friendly cleaning method that does not use harsh chemicals or solvents.

Ultrasonic cleaning is a process that uses high-frequency sound waves to clean electronic components and other materials. Ultrasonic cleaning is necessary to ensure that electronic devices are free of contaminants, improve their functionality, and increase their reliability and durability.

Ultrasonic cleaning can remove dirt, dust, grease, grime, flux residue, and other contaminants that may accumulate on electronic components, PCB boards, or other parts during the manufacturing process.

Ultrasonic cleaning improves the quality of electronic devices by ensuring that they are free of contaminants. This reduces the risk of failure, improves reliability and longevity, and enhances overall performance.

Ultrasonic cleaning is a non-destructive process that does not require harsh chemicals or abrasive materials. This means that electronic components and other materials can be cleaned without damage or degradation.

Ultrasonic cleaning is a cost-effective process compared with manual cleaning methods. It is faster, more efficient, and requires fewer resources, making it ideal for high-volume manufacturing.

Ultrasonic cleaning is an eco-friendly process because it uses less water and energy compared to other cleaning methods. This reduces environmental impact and helps companies to meet sustainability goals.

Ultrasonic cleaning is useful in cleaning a wide range of electronic components and PCBA. Manufacturers should consider ultrasonic cleaning for any PCBA that requires thorough cleaning to ensure optimal performance and longevity. Here are some types of PCBA that may require ultrasonic cleaning:

SMT Assemblies: Surface Mount Technology (SMT) assemblies use small surface-mount components, which may be difficult to clean manually. Ultrasonic cleaning can efficiently remove the flux residue and other contaminants that accumulate on these components during the manufacturing process.

Through-Hole Assemblies: Through-hole assemblies use larger components with leads that pass through holes drilled into the PCB. These components may also accumulate contaminants during manufacturing, making Ultrasonic cleaning an effective option for removing these contaminants.

High-Reliability Applications: Electronic devices used in high-reliability applications like aerospace, medical, and military equipment require very high levels of reliability. Ultrasonic cleaning can ensure that these devices are free of contaminants that could affect their performance.

Complex PCBA: Complex PCBA with multiple layers, fine-pitch components, and high-density interconnects are often challenging to clean manually. Ultrasonic cleaning can penetrate deep into complex structures, ensuring that all contaminants are removed.

Fine-Pitch Components: Fine-pitch components, such as Ball Grid Arrays (BGA), Quad Flat No-Lead (QFN), and Chip Scale Packages (CSP), have small gaps between pins where flux residues may accumulate during soldering. Ultrasonic cleaning can remove these residues without affecting the component's functionality.

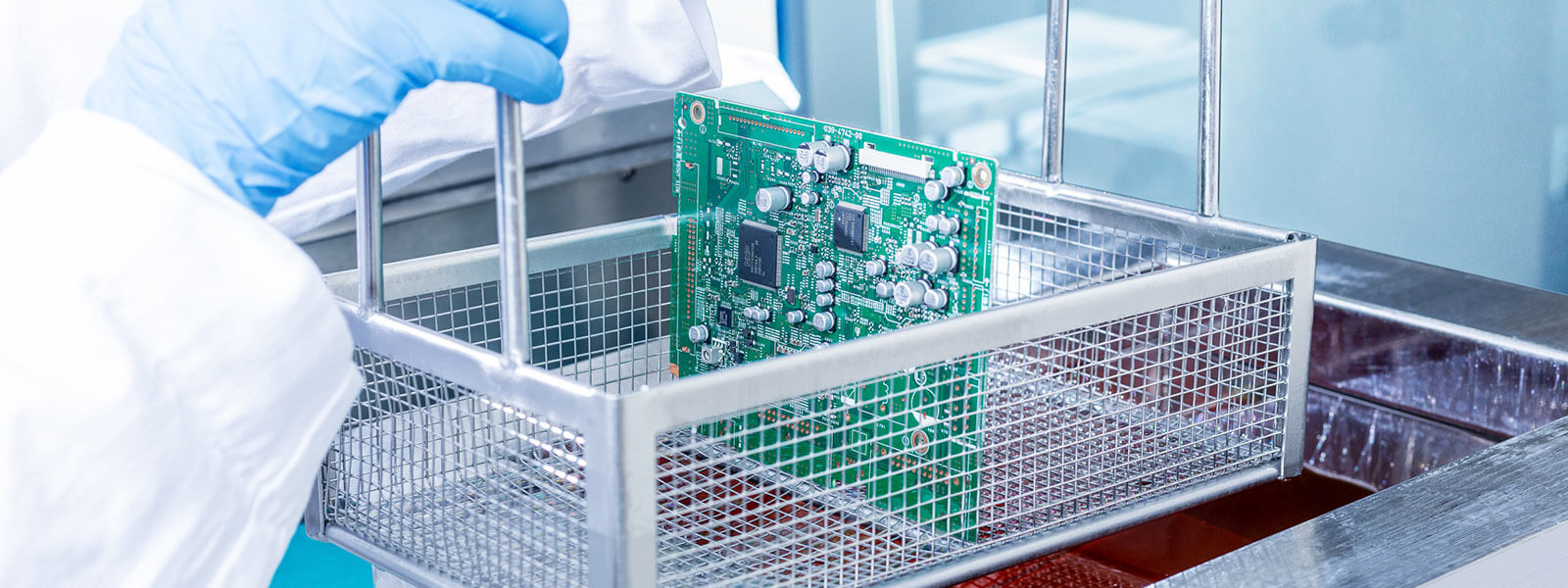

Ultrasonic PCB cleaning is a process of cleaning Printed Circuit Board Assemblies (PCBA) using high-frequency sound waves. Here are the steps involved in Ultrasonic PCBA cleaning

The first step is to prepare the PCBA for cleaning by removing any loose debris or contaminants using compressed air, brushes, or other appropriate tools.

The PCBA is then loaded into the Ultrasonic cleaner tank, which contains a cleaning solution. It is essential to make sure the cleaning solution is compatible with the materials used in the PCBA and the type of contaminants being removed.

The Ultrasonic cleaner produces high-frequency sound waves that create tiny bubbles in the cleaning solution. These bubbles collapse, creating a scrubbing action that removes contaminants from the PCBA. The duration and frequency of the Ultrasonic cleaning depend on the type and extent of contamination.

After Ultrasonic cleaning, the PCBA is rinsed thoroughly in clean water to remove any remaining cleaning solution.

Once the rinse is complete, the PCBA is dried using compressed air, a vacuum, or a drying oven. It is important to ensure that the PCBA is dry before proceeding to the next step.

A post-cleaning inspection is conducted to verify that all contaminants have been removed. Visual inspection, electrical testing, and other methods can be used to check for cleanliness and functionality.

Ultrasonic PCBA cleaning is an effective way to remove contaminants from the surface of electronic components, especially those that are difficult to clean manually or contain sensitive parts. By following these steps, manufacturers can ensure that the PCBA is free of contaminants, reliable, and long-lasting.